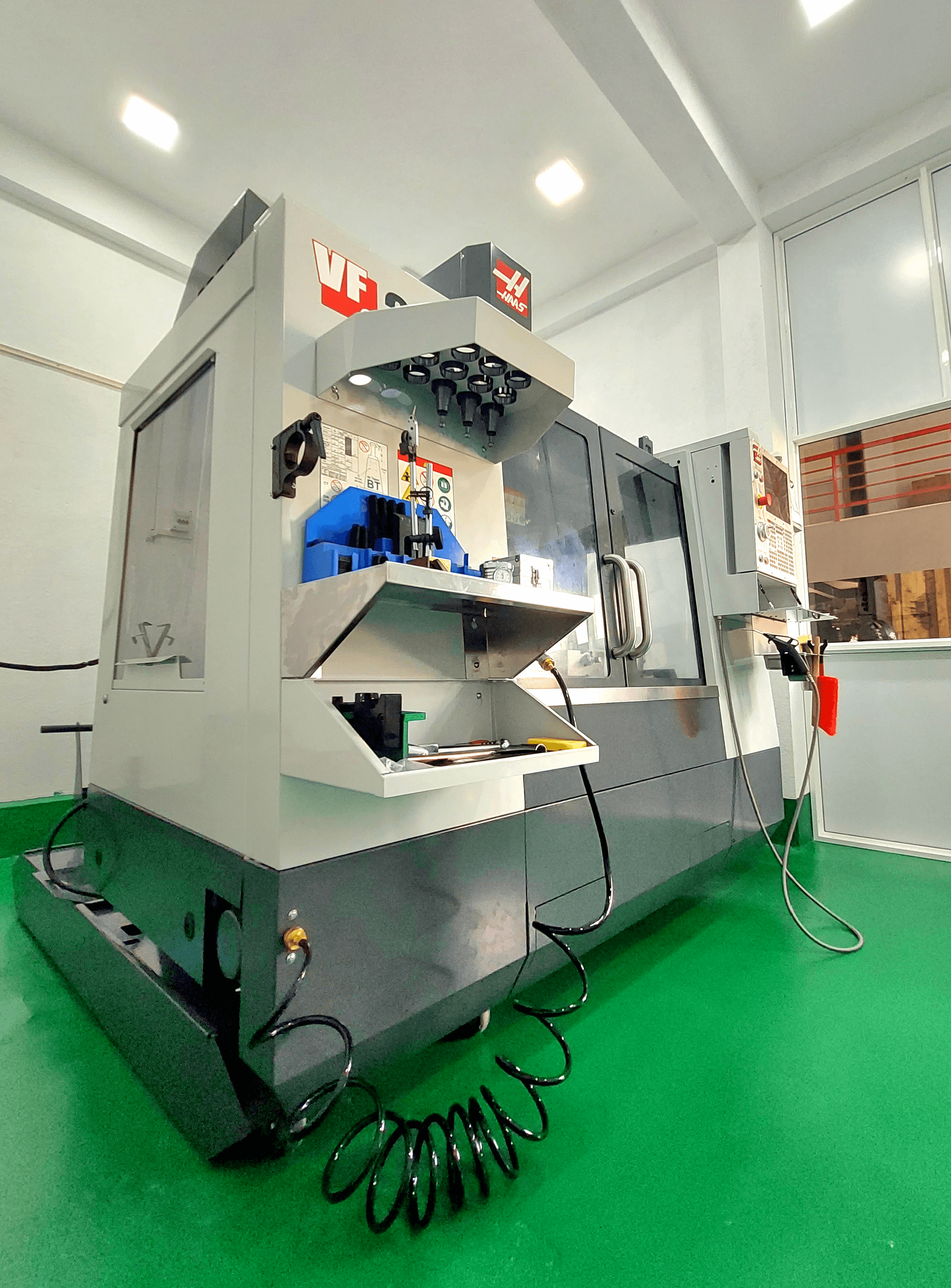

CNC Machine Center

The company prides itself on its cutting-edge CNC manufacturing technology, employing state-of-the-art equipment such as the Hass VF2 CNC vertical milling machine for both part and mould fabrication. This advanced technology ensures precision and efficiency throughout the manufacturing process, allowing for high-quality production and customer satisfaction.

CNC machining stands for Computer Numerical Control machining, a subtractive manufacturing process where computer software dictates the movement of factory tools and machinery. It is an essential technology in the creation of moulds and parts for various industries due to its precision and repeatability. The process begins with a CAD model that represents the final product's design. This model is then converted into a CNC program, which translates it into instructions that the CNC machine can execute. The machine typically operates with drills, lathes, and mills to carve out the desired shape from a solid block of material, usually metal or plastic.

For mould manufacturing, CNC machining is particularly advantageous because it can produce complex shapes with tight tolerances that are often required in moulds. These moulds are then used in injection moulding or die casting processes to create final parts at a high volume. The ability of CNC machines to operate with a variety of materials and to switch between different tools allows for the manufacture of intricate and precise components. Whether for prototyping or full-scale production, CNC machining is pivotal in ensuring that the moulds and parts produced have the exact specifications and finishes needed for high-quality end products.